World Exclusive: New Low Currant Design for SoC Module

ByteSnap Design unveils the latest microprocessor orientated in a unique new vertical market.

Featuring low currant design, this microchip is about to send shock waves through the electronics industry. We’ve seen the migration of electronics – from gadgets used in the home/office, to tech you can travel with and even wear.

The use of organic components in electronics such as OLEDs, batteries and solar cells, has become increasingly common in the last few years; the main drawback being the limit to the number of organic transistors that could fit on a chip.

Until now.

We can now reveal that our experts here at ByteSnap have discovered that by forming a suitable organic substrate into the form of a sponge, they can a vastly increase in the surface area on which to construct chip logic.

This exciting breakthrough elevates technology to the next level, creating a whole new cutting-edge sector – ‘edibles’.

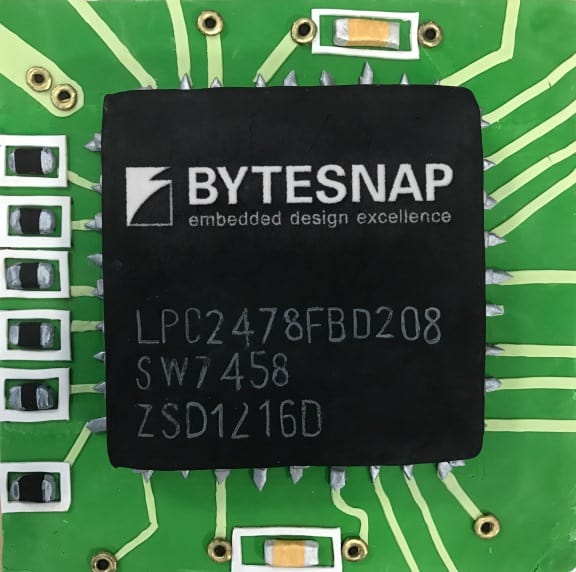

In a world exclusive, the ByteSnap Design ASIC team reveal the first teardown of the chip – walking you through its low currant design and how it’ll inspire you to change your perception of electronics.

First impressions show the new device has been designed with a fresh look.

The transition from Silicon wafers to Sucrose wafers is a bold move, but is a key ingredient to allowing this to be more palatable to both product developers and end users in 2017 and beyond.

Revolutionary SoC module for the new Edibles market

The part is based around a 26cm – 36 pin QFN package. The dimensions are incredible and will be hard to swallow for some – but it’s recently been agreed by ByteSnap management that the new 5cm manufacturing process will be scaled down for production sucrose later in the year.

Upon closer inspection we detect that the low currant chip has been designed with IOT (Icing On Top) with the option for M2M (Marzipan 2 Marzipan) fillings. When we take a cross section of the chip we can really see the quality of the engineering:

There are some surprising changes when adopting this low currant design technology.

Traditional wave soldering and reflow ovens will need updating to support more old school piping bags and gas ovens, although apparatus such as fume extraction can stay the same as fumes from the board production process are considerably less toxic.

The toxins and chemicals in traditional PCB and chips can be harmful to wildlife and humans. This can mean a very negative environmental impact as products become end of life and require specialised recycling or waste disposable.

This new range of edibles now gives us a much simpler solution to the problem with only limited side effects if too much ‘tech’ is consumed in a short period of time:

In summary, we are very proud of the new chip design. On reflection, we’d prefer a reduction in size but this will be addressed in future iterations.

Our biggest challenge, which we’ve yet to overcome, is shelf life.

Consumer parts are only guaranteed for one week and industrial parts (UHT) at good for 3 months. These high-cost industrial components will no doubt leave a bad taste in the mouths of consumers. The other issue we uncovered during the tear down….

….bugs.

As a precaution, production chips will be scanned for these unwanted creatures, which are currently only detectable either by close inspection or by their low buzzing emissions.

The SoC (System on Cake) Module will only be available on April the 1st.