BOM Monitoring Service: Drama-Free Component Obsolescence Management for Technical Directors

Avoid supply chain issues with proactive BOM monitoring

Why does BOM monitoring matter for product lifecycle management?

Component obsolescence is inevitable—microcontrollers, power supplies, and operating systems all reach end-of-life. Without proactive BOM monitoring, manufacturers discover these issues only when production stops, forcing emergency redesigns that cost £30K-£100K+ and cause weeks of production delays. Continuous monitoring identifies lifecycle risks before they become crises, allowing strategic component transitions rather than panic responses.

What is OMaaS?

OMaaS - Obsolescence Management as a Service - is ByteSnap Design's BOM Monitoring Service. It provides you with continuous, proactive oversight of your product's component health—so your engineering team can focus on innovation, not administrative parts checking.

OMaaS is a monthly subscription service monitoring component lifecycle status, assessing impact, and recommending action before obsolescence disrupts production.

Since 2008, we've helped UK technical directors reclaim hundreds of engineering hours previously lost to reactive BOM management.

The Hidden Cost of Reactive BOM Management

Technical directors tell us the same story: their factory emails about component status changes, pulling engineers away from strategic projects to investigate whether a parts notification actually matters.

Sometimes action is needed.

Often it’s noise.

Either way, it consumes valuable technical leadership time.

The typical pattern we see:

Your contract manufacturer flags a component change. Your team stops current work to check if it’s equivalent. You review datasheets, contact distributors, assess schematic impact, then recommend action—or discover it was a non-issue.

Repeat weekly.

This reactive approach costs valuable engineering hours each month, distracts from innovation, and creates constant context-switching that kills productivity.

For companies who’ve lost key technical staff or lack dedicated production resources, the problem intensifies.

Product knowledge lives in people’s heads. When those people leave or get stretched thin, component decisions slow down or get missed entirely until parts become genuinely unavailable—turning manageable updates into production crises.

OMaaS: Proactive BOM Health Monitoring

ByteSnap Design’s Obsolescence Management as a Service works differently. We become your outsourced BOM management team, continuously monitoring component lifecycle status and filtering real issues from distractions – so you only engage when expertise is truly needed.

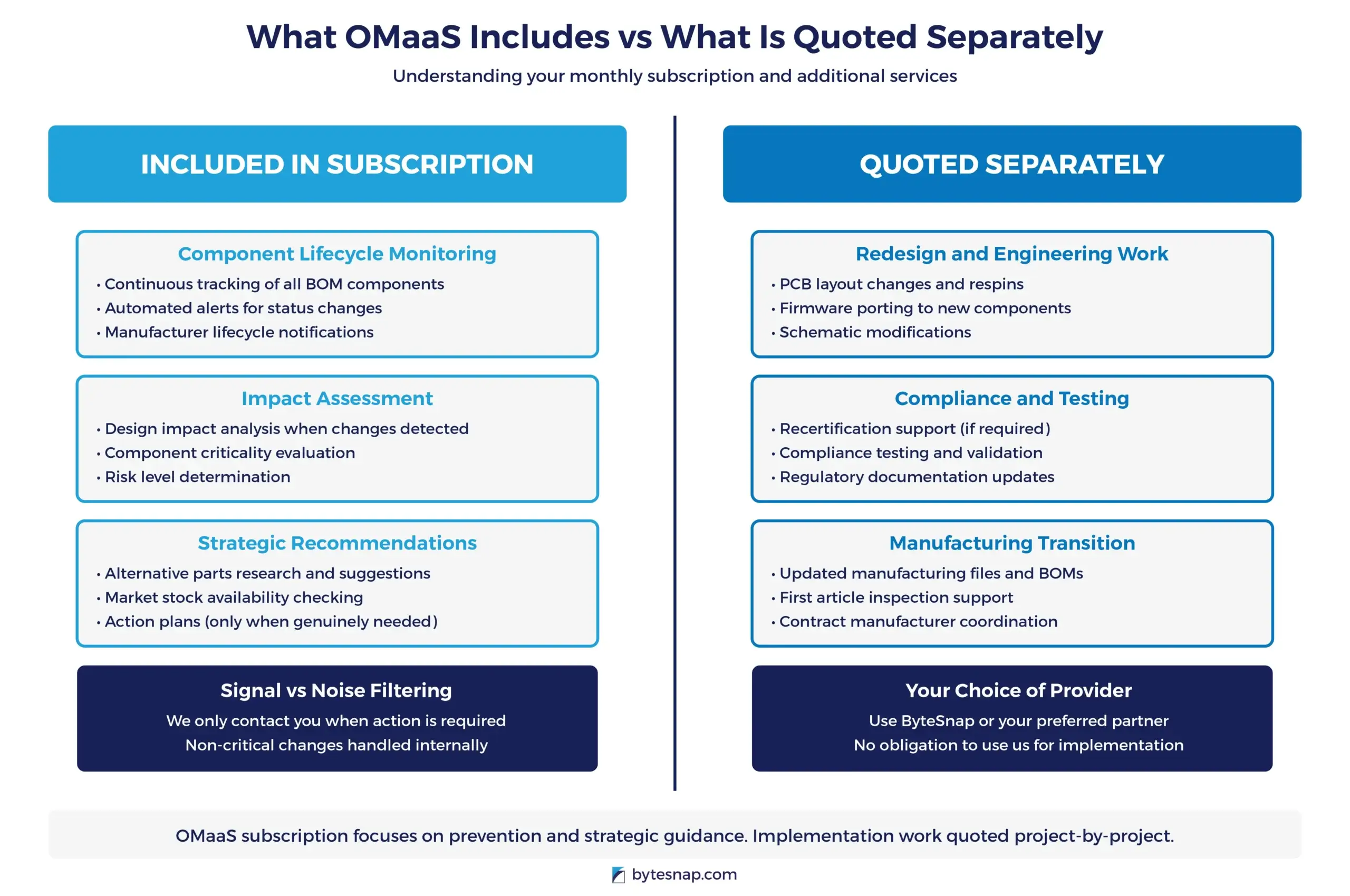

What's Included in Monthly Monitoring

Your subscription covers:

- component lifecycle tracking across your product’s entire BOM

- impact assessment when status changes occur

- alternative parts research and availability checking, strategic recommendations with filtered noise

- and supply chain intelligence from our distributor partnerships.

How does proactive BOM health monitoring work?

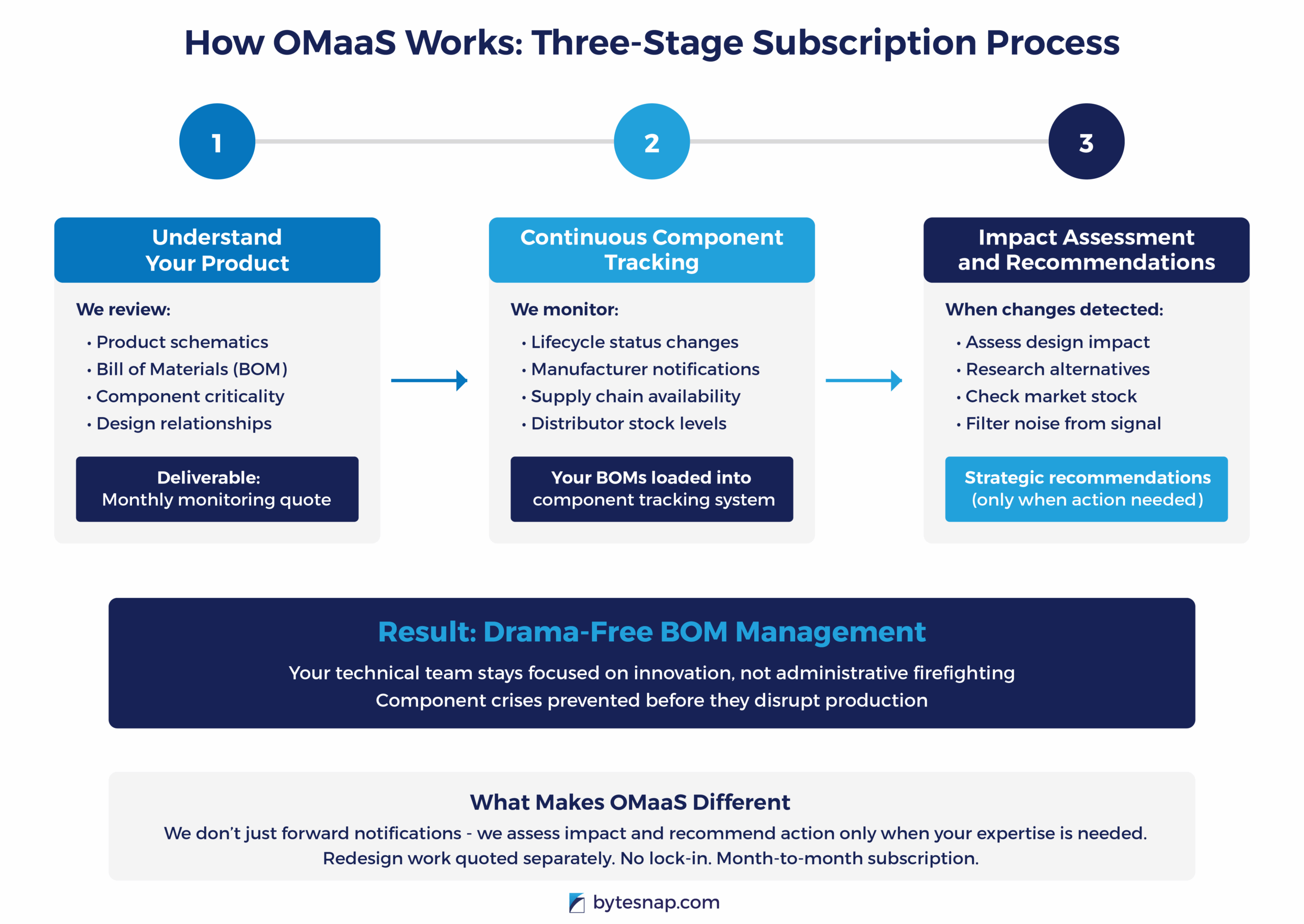

Proactive BOM health monitoring is a three-stage process:

Stage 1: Understand Your Product

Our engineering team reviews your schematics and BOM to understand component relationships, criticality, and potential risks. We prepare a monthly monitoring quote based on your product's component count and complexity. No long-term contracts—month-to-month subscription.

Stage 2: Continuous Component Tracking

We load your BOMs into our component tracking system with alerts configured for lifecycle status changes. Our long-standing supply chain relationships with major distributors provide early visibility into component availability shifts before they become critical.

Stage 3: Impact Assessment and Strategic Recommendations

When component status changes, we don't just forward notifications. We assess impact against your specific design, research alternative parts and market stock availability, then provide strategic recommendations—only contacting you when decisions or actions are genuinely required.

Minor equivalent changes that don't affect your design? We handle it.

Critical part requiring board respin? You receive detailed assessment with options and cost implications.

Redesign work is quoted separately. If component changes require PCB layout updates, firmware porting, or compliance work, we provide clear project quotes.

You’re not locked in – use ByteSnap or your preferred provider. OMaaS is about preventing crises, not creating dependencies.

Who benefits most from BOM Monitoring?

This obsolescence management service, OMaaS, suits technical directors managing multiple products without dedicated production resources. We see particular value for:

- companies who've experienced key staff turnover and lost institutional BOM knowledge

- engineering teams stretched too thin for administrative component tracking

- products in stable production requiring lifecycle protection

- and organisations tired of reactive firefighting who want strategic, preventative management

Real Results: Obsolescence Crises Solved through BOM Monitoring & Redesigns

A UK heating controls manufacturer (high volume consumer product) needed help after years of factory-generated component alerts overwhelming their technical director.

Multiple products, frequent supplier notifications, unclear whether each change mattered.

We stepped in to carry out long term component monitoring for them, and liaise with Chinese factories to continuously optimise the customer’s BOM.

This allows the client’s engineering team to focus on next-generation product development instead of administrative BOM management.

When their ceiling-mounted air quality monitor’s Freescale microcontroller was discontinued, production faced a 6-month halt. We migrated to STM32 in 7 weeks.

Production resumed in 8 weeks versus 6+ months for a complete redesign, costing £45,000 versus £180K estimated.

Existing certifications were maintained with zero customer impact.

Multiple products relied on discontinued Windows CE with 10+ year customer support commitments.

We developed an Embedded Linux platform using Snap UI, replicating the interface whilst gaining modern security and connectivity—at a fraction of complete redesign costs.

Why ByteSnap Design for Component Monitoring?

- Embedded electronics expertise since 2008 navigating component lifecycles, supply chain disruptions, and manufacturer transitions. Our team understands not just part numbers, but circuit design implications—critical for accurate impact assessment.

- Supply chain visibility through long-standing relationships with major semiconductor vendors and distributors. We track lifecycle announcements, allocation situations, and alternative availability before public notifications.

- ISO 9001:2015 certified processes ensure consistent, documented BOM tracking methodology. Your subscription includes audit trail of all component assessments and recommendations.

- Component tracking infrastructure purpose-built for electronics monitoring. We've invested in tools and processes specifically for this service—capabilities most manufacturers can't justify building internally.

- No conflicts of interest. Unlike contract manufacturers who may recommend changes favouring their inventory or capabilities, our assessments focus solely on your product's best interests. We'll recommend the simplest, lowest-cost path forward—even when that's "no action required."

Could your company benefit from outsourced component monitoring?

BOM Health Self-Assessment

For Technical Directors and Engineering Managers

Does your organisation need proactive BOM monitoring? Score each statement to assess whether outsourced component lifecycle management would benefit your team.

Scoring Guide: