Stop Manufacturing Nightmares - Protect Your Firmware IP

Secure my manufacturing process

When Manufacturing Security Fails, Everything Collapses

The Reality Every Electronics Company Faces

You’ve invested years developing innovative firmware that differentiates your products from competitors. Now you need to scale manufacturing, work with contract manufacturers across multiple countries, and maintain consistent quality.

One security breach or quality failure can destroy everything you’ve built.

Contract electronic manufacturers require firmware access for device programming, creating opportunities for proprietary code extraction and reverse engineering.

Manufacturing blind spots hide quality issues until customers discover defective products.

The cascading damage is permanent: IP theft eliminates competitive advantage, devalues R&D investment, destroys customer trust, and forces companies out of business.

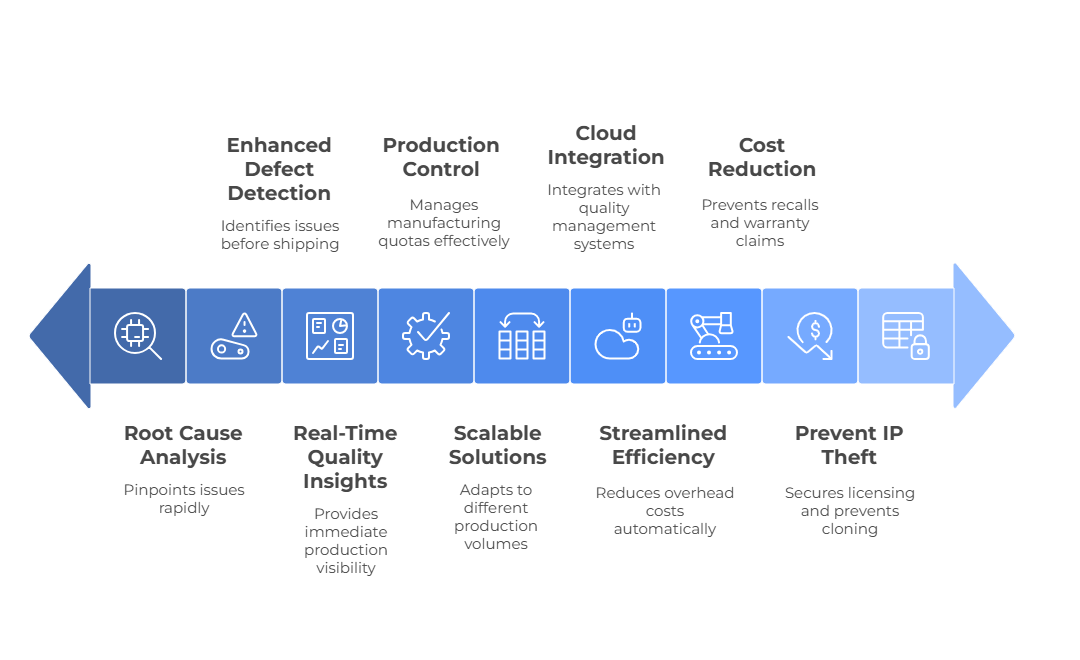

Nine Ways SNAPPRO IQ Eliminates Manufacturing Risks

Secure licensing protocols prevent unauthorised hardware design cloning. Dynamic encryption protects proprietary firmware whilst device-specific keys render stolen files useless to competitors.

Capture detailed PCBA data for immediate analysis across manufacturing facilities. Real-time monitoring provides instant visibility into production metrics, enabling rapid response to emerging issues.

Identify manufacturing issues before products leave the factory. Advanced analytics detect systematic quality problems that traditional testing misses, preventing defective products reaching customers.

Quickly pinpoint manufacturing problems through comprehensive device traceability. Immutable audit trails enable rapid identification of specific conditions, equipment, or processes causing defects.

Access secure production data through third-party quality management integration. Cloud architecture ensures seamless global data sharing whilst maintaining strict security protocols.

Customised implementations for prototype runs and high-volume production. SNAPPRO IQ adapts to different manufacturing environments and requirements without wholesale process changes.

Assign manufacturing quotas that cannot be exceeded without authorisation. Usage-based licensing ensures precise volume control whilst preventing unauthorised overproduction or IP exposure.

Minimise expensive rework and eliminate field failures before they occur. Intelligent quality control prevents costly recalls, warranty claims, and support issues damaging profitability.

Reduce manufacturing overhead whilst maintaining superior quality standards. Automated testing and comprehensive logging eliminate manual processes, reducing labour costs and human error.

ByteSnap Design - Electronics Engineers Who Understand Your Challenges

As electronics engineering specialists, we understand the anxiety of transferring valuable IP to contract manufacturers. We’ve witnessed engineering teams struggle with quality issues that waste development time and damage customer relationships.

Sixty Years of Electronics Engineering Experience

ByteSnap combines over 60 years of electronics engineering expertise in SNAPPRO IQ development. Our engineers have confronted the same IP security and manufacturing oversight challenges you face, embedding real-world manufacturing knowledge into a platform designed for genuine engineering problems.

Three Steps to Manufacturing Security and Quality Control

Manufacturing Security Assessment

Our engineers analyse your production processes and identify every potential IP exposure point across manufacturing partnerships.

Seamless SNAPPRO IQ Integration

We configure SNAPPRO IQ to integrate with existing workflows without disrupting production whilst training your teams.

Protected Global Manufacturing

Launch with complete firmware IP security, real-time oversight, and intelligent quality control across all production partners.

How SNAPPRO IQ Transforms Electronics Manufacturing Security and Quality

SnapPro IQ is ByteSnap’s automated PCBA test solution that streamlines quality control and protects your intellectual property.

Assign unique identifiers to each board, capture full test data, and track production securely in the cloud.

SnapPro IQ helps prevent hardware cloning and gives you complete control over your products, wherever they’re made.

Ideal for small to mid-sized electronics manufacturers, SnapPro IQ offers enterprise-level testing without a major investment. Detailed insights allow rapid fault tracing, reducing delays and stopping defective PCBAs from reaching customers.

Proven in both small-batch and high-volume environments, SnapPro IQ can be tailored to your testing needs, improving accuracy, speeding up issue resolution, and cutting the cost of failures.

“Our approach focuses on designing for test and manufacture from the ground up. This strategy ensures that we can access necessary test points during production, implement a comprehensive testing strategy without compromising the product’s design, and prevent costly redesigns or manufacturing issues down the line.”