TL;DR - Key production ready BOM points for electronics manufacturers

What is a Bill of Materials (BOM)?

A BOM is the comprehensive master document listing every component and sub-assembly needed to manufacture your product. For managing directors, it's not merely a technical spreadsheet; it's a strategic business document that directly impacts margins, production schedules, and product longevity.

What makes a BOM "production-ready"?

A production-ready BOM includes not just component lists but also lifecycle data, qualified alternatives, and complete supplier information, protecting your margins from supply chain disruption.

Why does this matter to your bottom line?

A poorly managed BOM costs UK manufacturers 5-15 engineering hours monthly per product in reactive firefighting, delays production schedules, and can force expensive redesigns years into full-scale production.

What should you expect from your engineering team?

Your team should deliver BOMs with component lifecycle tracking, pre-qualified alternatives for critical parts, and clear version control, not just a list of parts that work today but might fail tomorrow.

Contents

Why production ready BOMs are key for electronics manufacturing success

In electronics manufacturing, a poorly managed Bill of Materials or BOM goes beyond being a technical issue; it’s a business risk that directly threatens your margins, delivery schedules, and competitive position.

As a senior manufacturing decision-maker, you rely on your engineering team to deliver production-ready BOMs that won’t cause expensive surprises months or years down the line.

Drawing on 17 years of supporting UK manufacturers, we’ve seen how strategic BOM management separates companies that scale smoothly from those constantly firefighting component crises.

The difference?

Engineering teams that build resilience into BOMs from day one, rather than scrambling when parts become unavailable.

How do production-ready BOMs protect your business? What are the real costs of reactive BOM management?

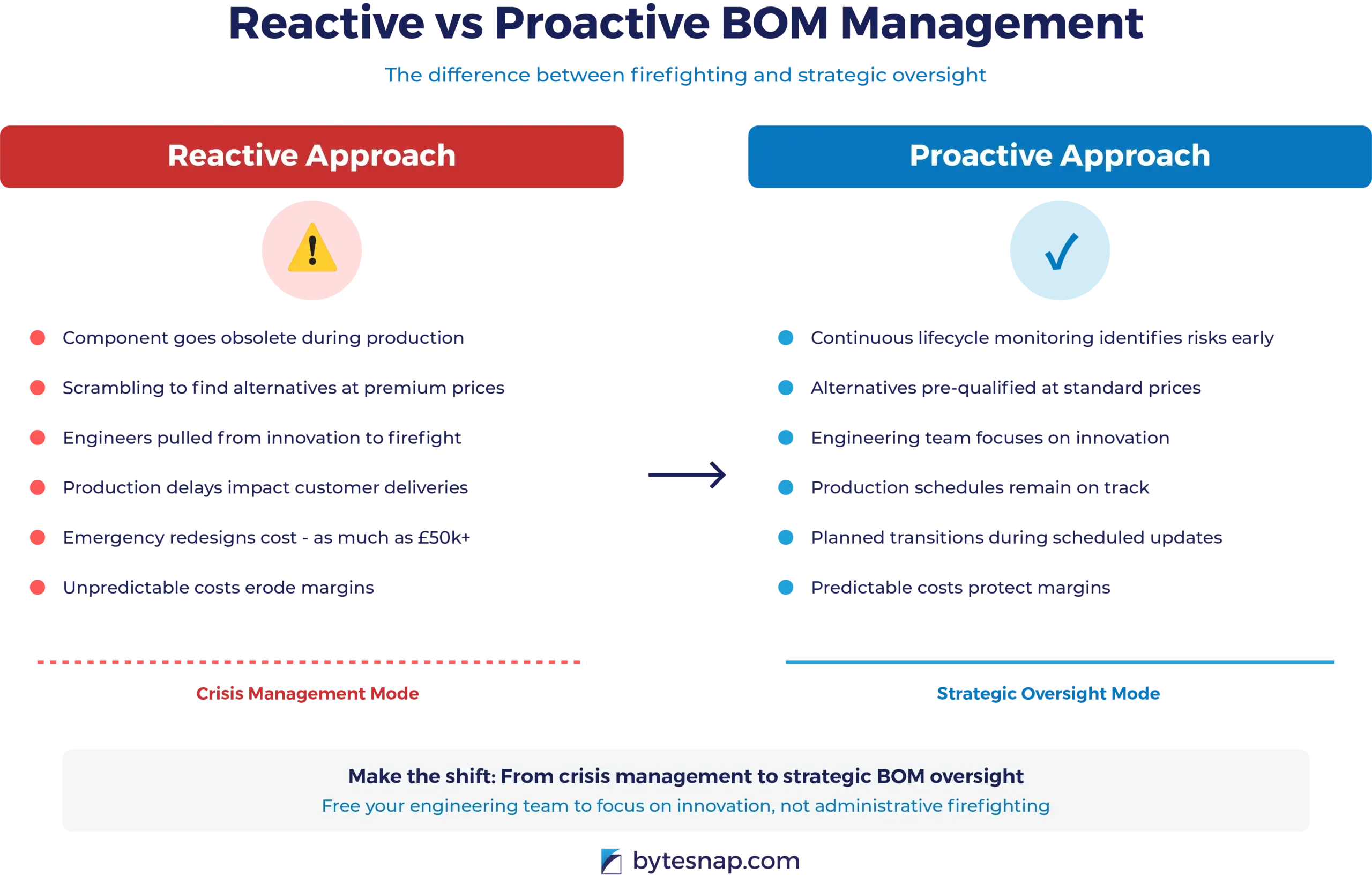

UK manufacturers typically spend 5-15 engineering hours monthly per product investigating component alerts and supplier notifications.

For companies managing multiple products, this administrative burden pulls your technical leadership away from innovation and new product development.

The hidden costs multiply when you consider:

- Production line stoppages due to component unavailability

- Expensive board re-spins when alternatives aren't pre-qualified

- Emergency air freight to maintain delivery commitments

- Margin erosion from last-minute component substitutions at premium prices

What should your engineering team include in a production ready BOM? Which core requirements can't be compromised on?

Your engineering team should provide these fundamental elements for every component:

Part Numbers and Identification Every component needs a unique Manufacturer Part Number (MPN) ensuring procurement teams order the exact part specified. Reference Designators (such as U1, R12) help manufacturing teams place components in correct PCB locations. Without these basics, production errors become inevitable.

Clear Descriptions and Values Detailed descriptions including electrical values (for example, 470µF capacitor) prevent costly procurement mistakes. This precision ensures accuracy throughout design and manufacturing processes.

Manufacturer and Supplier Information Knowing who manufactures each part and who can supply them is critical for manufacturability. This information enables smooth handover to manufacturing partners. Best practice: your engineering team should identify and qualify at least one alternative supplier for every mission-critical component during the design phase, protecting against future supply chain disruption.

Lead Times and Alternative Components Component delivery times directly impact production schedules. By documenting lead times and pre-approving alternative components, your team mitigates supply chain risks and prevents frustrating delays that damage customer relationships.

How does strategic BOM management mitigate risk?

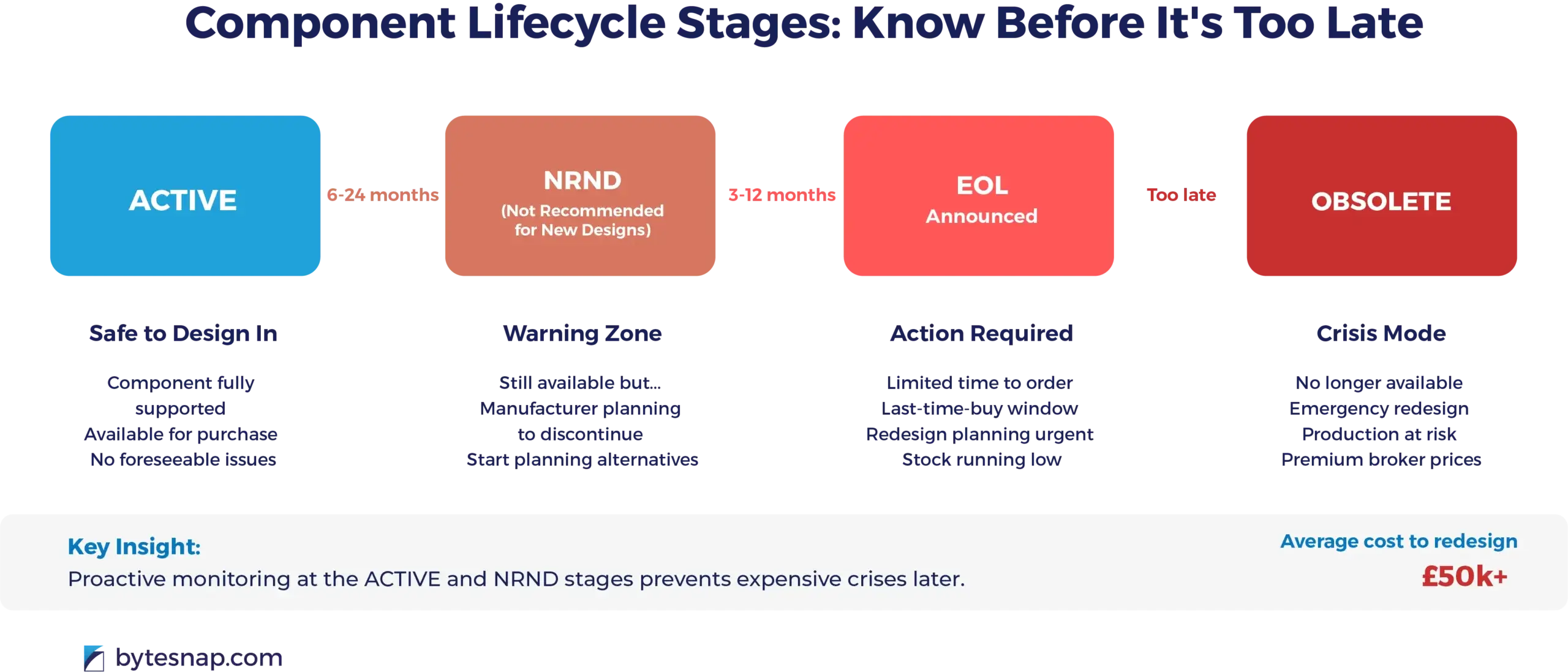

Component Lifecycle Monitoring: Electronic components often have shorter lifecycles than the products they're used in. We've witnessed components go obsolete mid-design—before boards even reach production. Without lifecycle tracking, you're vulnerable to expensive redesigns 2-3 years into full-scale manufacturing.

Strategic approach - ensure your engineering team tracks component lifecycle status (Active, Not Recommended for New Designs, End of Life) and identifies alternatives before parts become unavailable.

Ensuring Smooth Manufacturing Handover - Your BOM is the primary document you'll provide to manufacturing partners. If it's incomplete or inaccurate, expect production delays, expensive re-spins, and communication breakdowns. A well-organised BOM ensures seamless transition from engineering team to production line.

Controlling Costs and Protecting Margins: A detailed BOM enables accurate cost tracking for every component from initial prototype to final product. This visibility helps identify cost-saving opportunities and prevents over-ordering that ties up working capital.

Improving Cross-Functional Collaboration: A shared, properly maintained BOM ensures hardware, software, and procurement teams work from identical, current information. This collaboration minimises errors and improves overall product quality.

What best practices should you expect from your engineering team?

How Should Your Team Start the BOM Creation Process?

Your engineering team should generate preliminary BOMs directly from CAD software, ensuring reference designators and part numbers link directly to design files. Popular options include Altium Designer and Upchain.

Why Should BOMs Be Treated as Living Documents?

Your BOM will naturally evolve alongside your product design. As component specifications change, suppliers shift, or alternatives are qualified, your team should update the BOM immediately. Treating BOMs as static, one-time documents creates dangerous information gaps between engineering, procurement, and manufacturing teams. It's best to establish a culture where BOM updates are routine practice.

Why Is Version Control Critical?

The BOM must be updated with every design change. Implement robust version control systems that track all changes with clear revision numbers, dates, and modification descriptions. Without proper version control, teams waste hours reconciling discrepancies between design files and BOMs, leading to procurement errors and production delays. Your version control process should ensure everyone—from engineers to manufacturing partners—works from identical, current information.

Include Rich Component Data

Beyond basics, insist your team includes supplier-specific part numbers, lead times, and alternatives. This rich data makes the BOM invaluable for procurement and ensures your product remains manufacturable.

Implement Formal Review Processes

Before any BOM reaches manufacturing partners, a senior engineer or project manager should perform final accuracy and completeness checks.

Main questions to ask your engineering team

Use this framework to evalueate whether your team is deliverying truley production-ready BOMs:

- Does each component have a Manufacturer Part Number (MPN)?

- Are reference designators clearly documented?

- Is quantity per unit specified for every component?

- Do we have clear descriptions and electrical values?

- Have preferred suppliers been identified?

- Has the team identified alternative components for mission-critical parts?

- Do we know current lead times from chosen suppliers?

- Have we documented unit costs at target production volumes?

- Do we know the lifecycle status of every component?

- Are compliance requirements documented (RoHS, REACH, industry-specific)?

- Is the BOM in universally compatible format (.csv or .xlsx)?

- Does it have clear version control (revision number and date)?

- Has a senior engineer reviewed for accuracy and completeness?

What common BOM mistakes erode your margins?

Missing Component Data The most frequent issue: missing MPNs, quantities, or reference designators halt production before it begins.

Inconsistent Naming Conventions Using different naming conventions for identical parts causes confusion and procurement errors.

No Pre-Qualified Alternatives This leaves your production line vulnerable to supply chain shocks and causes major delays.

Static Document Management Treating BOMs as one-time documents rather than living files that evolve with design changes leads to version control disasters.

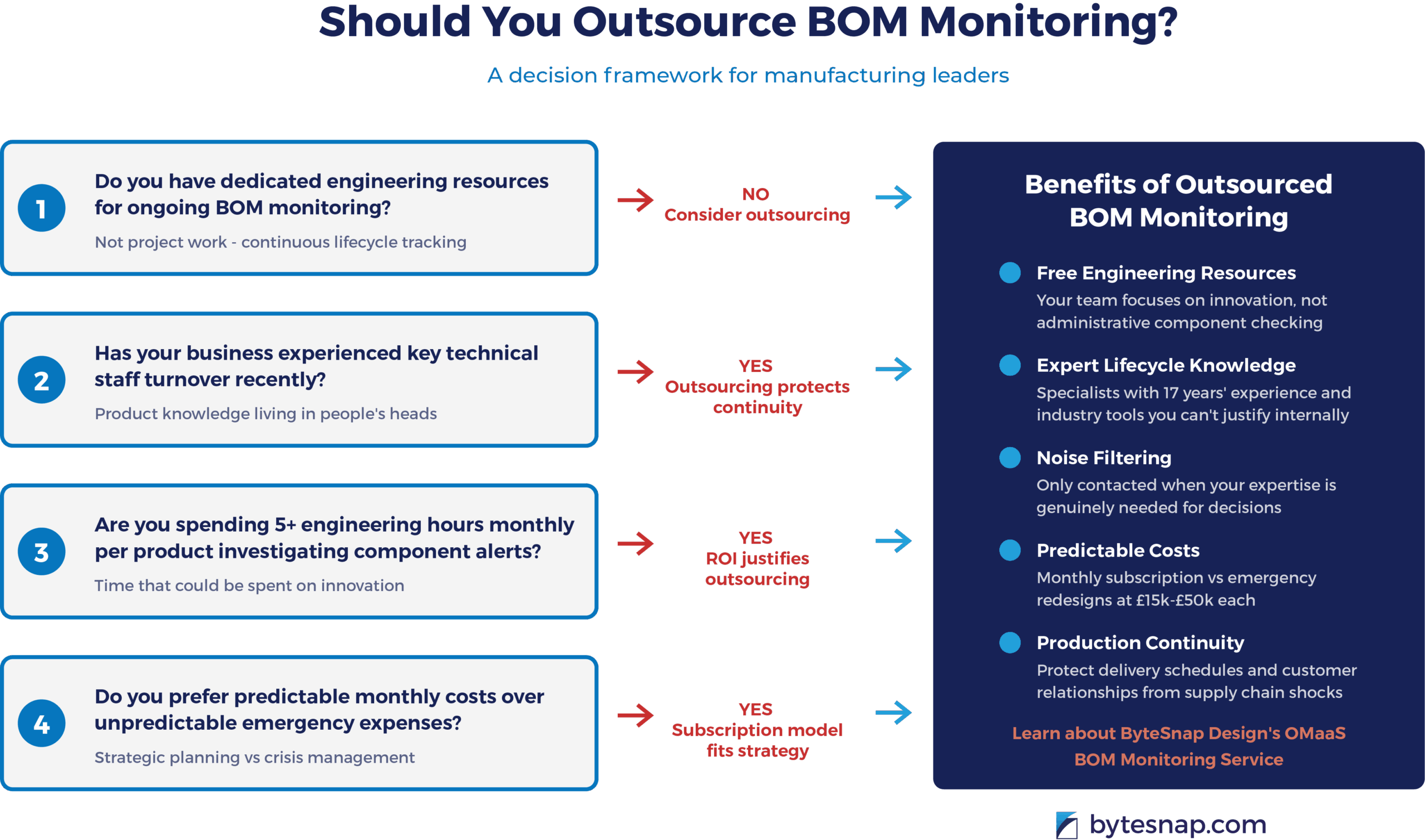

When should you consider outsourced BOM monitoring?

Many UK manufacturers lack dedicated resources for ongoing BOM management. If your business faces these challenges, outsourced monitoring might be strategic:

- Limited in-house engineering resources stretched across multiple priorities

- Key technical staff turnover where product knowledge exists only in people's heads

- Multiple products requiring ongoing lifecycle monitoring without dedicated production resources

- Reactive firefighting consuming valuable engineering time that should focus on innovation

For manufacturers preferring proactive strategic oversight rather than crisis management, outsourced BOM monitoring provides continuous component lifecycle tracking, impact assessment, and strategic recommendations.

This frees up your engineering team to focus on next-generation product development.

Learn more about proactive BOM monitoring services designed for busy technical directors.

Taking Control of Your BOM Strategy

Dunstan is a chartered electronics engineer who has been providing embedded systems design, production and consultancy to businesses around the world for over 30 years.

Dunstan graduated from Cambridge University with a degree in electronics engineering in 1992. After working in the industry for several years, he co-founded multi-award-winning electronics engineering consultancy ByteSnap Design in 2008. He then went on to launch international EV charging design consultancy Versinetic during the 2020 global lockdown.

An experienced conference speaker domestically and internationally, Dunstan covers several areas of electronics product development, including IoT, integrated software design and complex project management.

In his spare time, Dunstan enjoys hiking and astronomy.