TL;DR

The tipping point for moving from a PLC (Programmable Logic Controller) to a custom PCB (Printed Circuit Board) is when your production volumes, commercial targets, and product requirements outgrow what PLCs can cost-effectively deliver.

This change typically makes sense when:

- Your annual production is approaching 100–1,000 units or more and you see further growth ahead.

- PLC costs are eating into your margins or making your products less competitive in the market.

- You require advanced features, such as custom interfaces, tighter security or IoT/cloud integration.

- Space and integration matter: When minimising product size and integrating control, connectivity, and custom hardware in a single platform is critical to your success.

- Obsolescence and lifecycle risks are increasing: Vendors are discontinuing models, or you need long-term supply stability.

- NOTE ON STANDARDS: Compliance with new standards (e.g., cyber resilience) will be handled by the PLC manufacturer, so it isn’t a reason to move away from PLC.

New requirements (e.g., ATEX, SIL) can be handled through PLC, with expensive approvals managed by the manufacturer. However, they may not be as flexible and tailored as a custom design. Extra costs may also be incurred due to the potential need to move from an existing platform (even within the same manufacturer) to one which meets the new requirements.

What You’ll Learn

- How to identify the commercial tipping point for moving from PLC to a Custom PCB

- The key drivers and risks for technical decision makers considering this transition

- A step-by-step “tech tree” for choosing the right control platform at various production volume

- Real-world examples of cost savings and performance gains

- Practical guidance for de-risking your move and maximising ROI

Contents

Introduction: The Challenge for Technical Leaders

If you’re a technical director or engineering leader, you know all too well the pressure to deliver reliable, futureproof products while keeping costs under control.

When success builds from a product which used to be low volume and now is doing much better, how do you approach cost engineering the product to meet expected volumes. A solution for low volume is unlikely to be the best choice when volumes improve.

The reality is, the ground is shifting fast beneath UK manufacturers-and the risks of sticking with legacy PLCs are mounting.

As new capabilities become possible, PLC manufacturers are trying to shoehorn these into a PLC solution when perhaps the right approach is to step back and design something from scratch, which is fit for purpose.

Industry data shows manufacturers are under increasing pressure

Obsolescence and Disruption Are the New Normal:

Nearly 27% of engineering managers in UK manufacturing encounter issues related to technological obsolescence at least once a quarter, according to our industry research, and 61% face them at least once a year.

That means most teams are fighting fires with outdated control hardware, risking costly downtime and missed deadlines.

Cost Pressures Are Relentless:

A staggering 77% of manufacturers say the cost of upgrading existing systems is their greatest challenge in managing obsolescence, with 61% citing cost constraints as the main barrier to adopting new technologies.

When PLC costs start eating into your margins, every delay in modernisation is money lost.

Skills Shortages Compound the Problem:

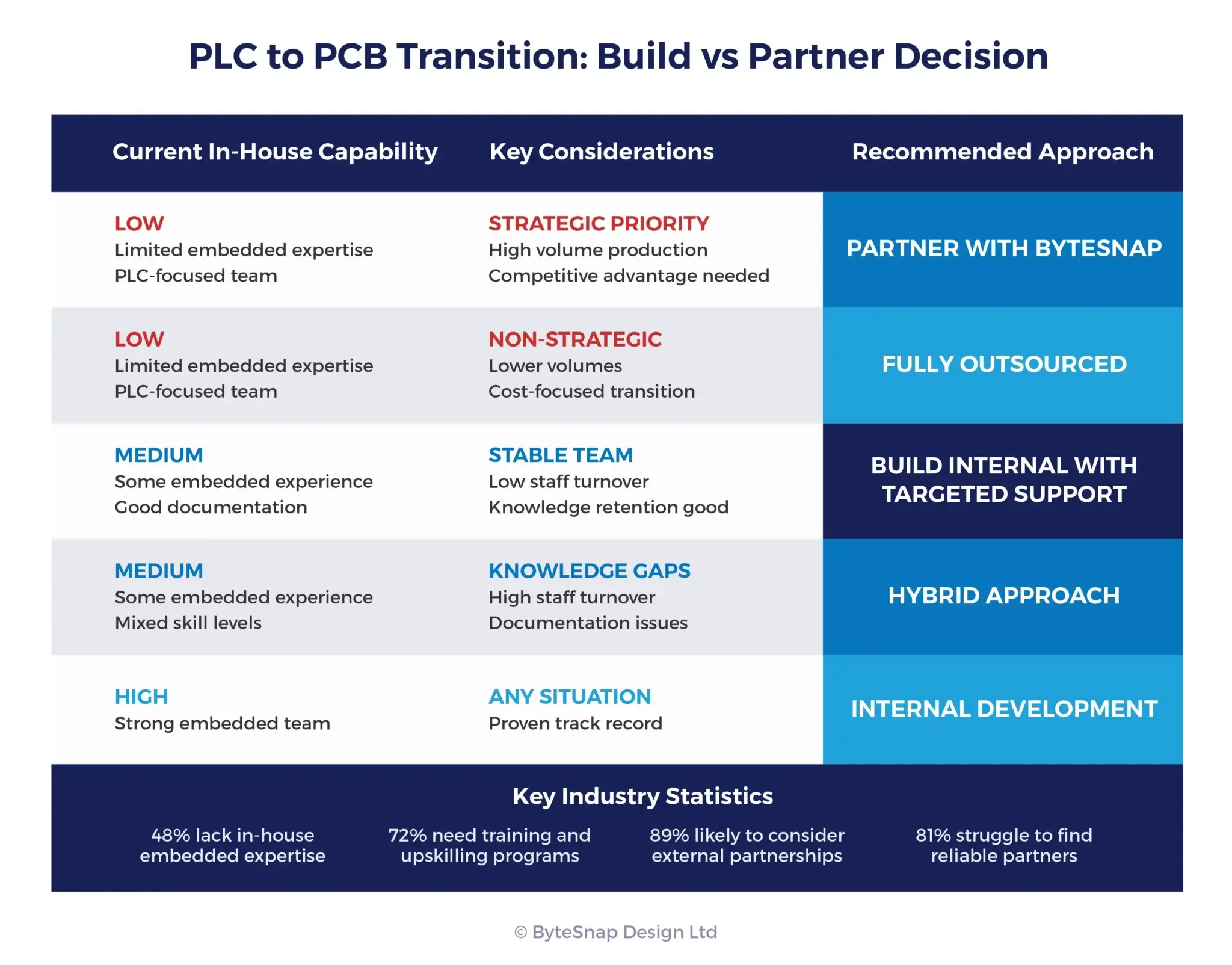

Almost half (48%) of manufacturers lack the in-house expertise to implement new technologies, making transitions even more daunting and increasing the risk of falling behind competitors.

The Race to Modernise Is On:

60% of manufacturers rate adopting new technologies-like IIoT, AI, and custom electronics-as “very important” to staying competitive, and 35% are already investing in custom electronics design and development to address obsolescence and cost pressures.

Strategic Partnerships Are Key:

72% of successful manufacturers now rely on external technology partners to overcome expertise and cost barriers, accelerating their move away from legacy systems.

If you’re still relying on PLCs for higher-volume production, you’re risking higher costs.

You’re also gambling with your ability to compete and deliver.

In this guide, you’ll discover how to identify the tipping point for moving from PLC to bespoke PCB, what’s driving the shift across the sector, and how to make the transition with confidence and commercial clarity.

The Technology Progression: Where PLCs and PCBs Fit

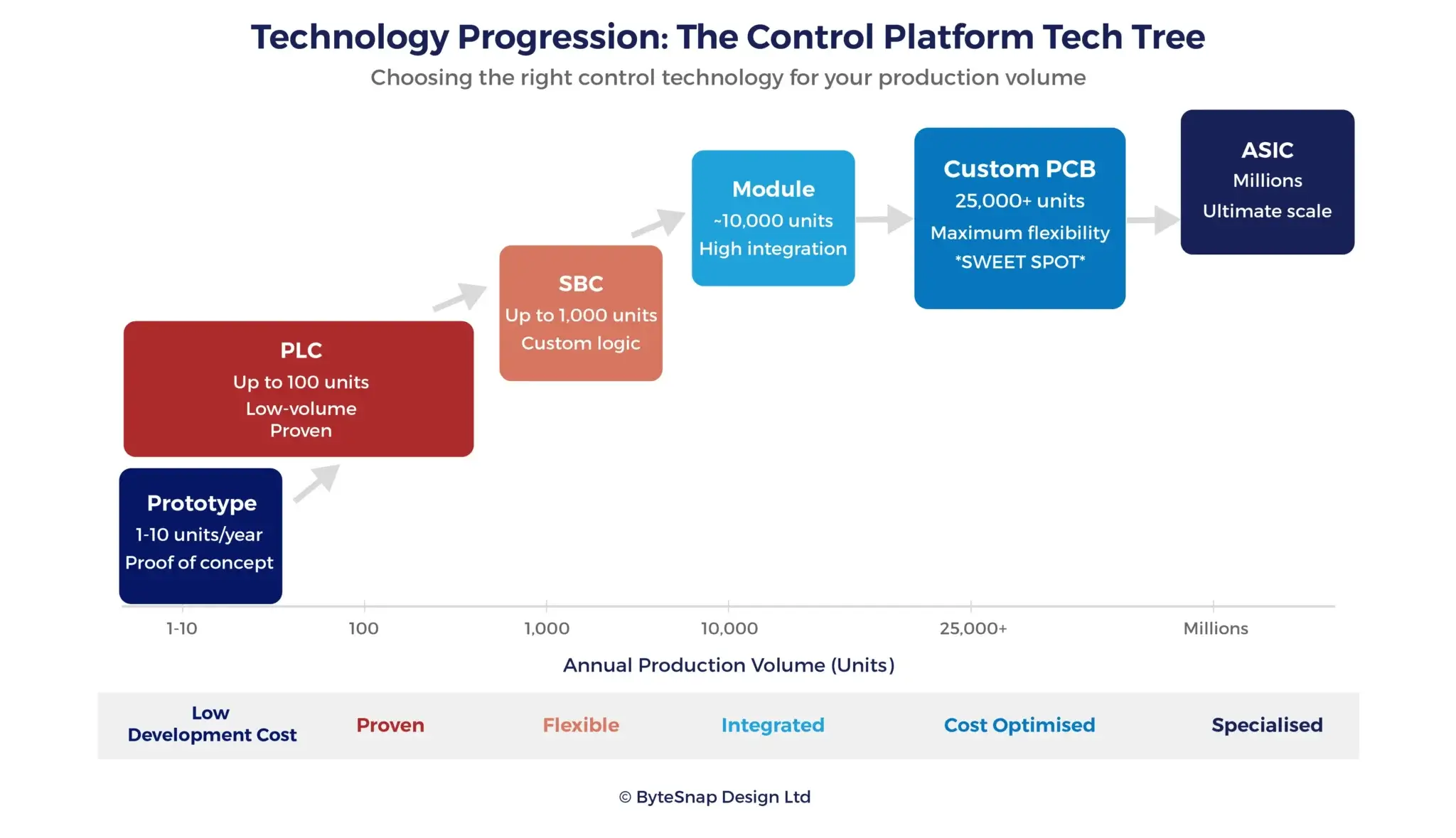

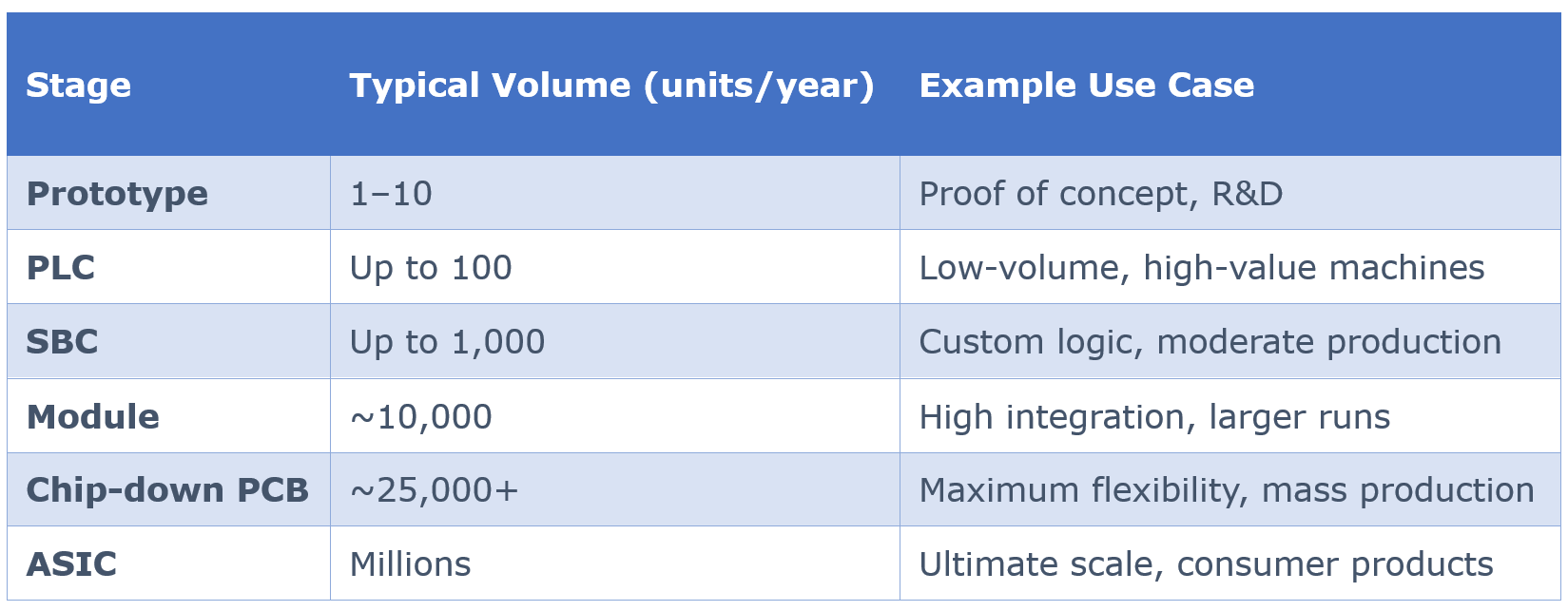

Think of your control technology choices as a “tech tree”, with each branch suited to different volumes and business needs. This is provided as a very crude rule of thumb for looking at the most suitable design for different volumes.

Clearly if you have a device which is doing something very simple and you have a low-cost PLC, it is hard to justify development costs for a PCB. Likewise, for some high-value devices, the cost of the PLC is negligible compared to the sale price and business as usual may be the right choice.

For other situations this could be a useful guide:

Why Move from PLC to Bespoke PCB? The Commercial Drivers

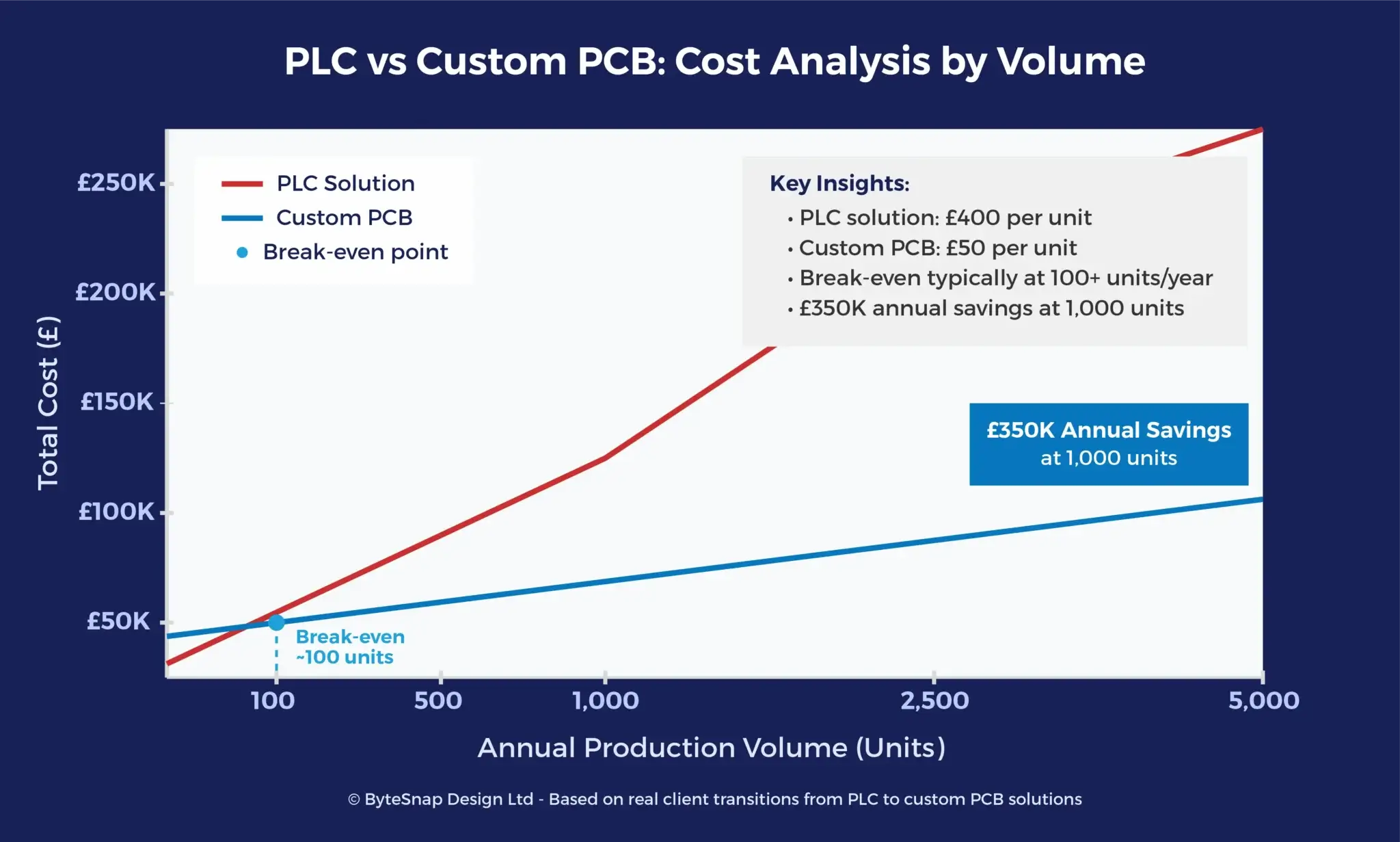

Cost Savings

PLCs are overkill for high-volume, simple control needs. A custom PCB can do the same job for a fraction of the cost. For example, an industrial product supplier replaced a £400 PLC/modem setup with a custom PCB costing under £50, saving over £350,000 in the first year at 1,000 units.

Integration and Space

A PCB integrates control, connectivity, and custom features directly into your product. This slashes wiring, reduces panel size, and simplifies assembly. For example, when using a PLC, a separate 4G gateway, and a display unit all of these could be condensed into a single board with the screen on the back.

Customisation and Performance

With a PCB, you tailor hardware and logic to your exact needs. No paying for unused PLC features, just the performance and interfaces you require.

Futureproofing and Security

Embedded PCBs are better suited for integrating cybersecurity, wireless, and cloud features, supporting your digital transformation and compliance goals.

Competitive Edge

A bespoke PCB lets you offer features, performance, and cost advantages your competitors can’t match with off-the-shelf PLCs.

When to switch from PLC to a custom PCB?

Volume: Approaching or exceeding 100–1,000 units/year, especially if growth is forecast.

Cost Pressure: PLC costs are eating into margins or making you less competitive.

Advanced Features Needed: Custom interfaces, Security features, IoT/cloud integration, or advanced real-time control are required. Keeping up with or staying ahead of the competition is hugely important.

Space/Integration Constraints: Miniaturisation or tighter integration is a priority.

Obsolescence and Lifecycle: Vendor discontinuations or a need for long-term supply stability.

Security and Compliance: New regulatory or customer demands for cybersecurity or certification (e.g. ATEX, SIL).

Working in industries that move fast emphasises how important it is to stay ahead of the competition.

It’s like watching evolution on fast forward, and you see winners and losers regularly.

As everything is affected by AI, this is speeding up the need for improvement and putting clear water between those who move forward and those who choose to bury their heads in the sand.

Challenges and How to Manage Them

- Development Time: Custom PCB design takes longer upfront-typically 6 -12months for specification, prototyping, software development and pre-certification work.

- Cost of Development: the cost of developing a bespoke PCB depends on a number of factors, the complexity of the control and the amount of software that is required being the main ones. Electronics design tends to be possible in typically 4-12 weeks, but software can be a great deal of work especially if it needs to be started from scratch. Designing a new product might cost in the region of £100,000 to £500,000 depending on complexity.

- Expertise Required: Embedded hardware and software design is specialist work. 48% of manufacturers cite in-house expertise gaps as a barrier.

- Reliability and Compliance: Industrial environments demand robust, validated designs and rigorous testing for CE standards and others like ATEX or SIL are more rigorous.

- Change Management: Transitioning from PLCs to PCBs will require process changes and assembly staff training.

Best Practices for a Successful Transition

- Start with Feasibility: Benchmark current PLC costs and performance against a potential custom PCB solution.

- Partner Well: Hire a team or choose a design partner with deep technical expertise, industry knowledge, and strong references.

- Pilot Projects: Test the PCB in parallel with your PLC before full rollout.

- Lifecycle Planning: Integrate obsolescence and supply chain management from the start-47% of firms now do this formally.

- Compliance Built-In: Design for cyber resilience standards and certifications from day one.

How ByteSnap Helps You De-Risk the Move

- End-to-End Expertise: From concept to production, including hardware, software, and compliance.

- Proven Track Record: 300+ embedded projects delivered across industrial, medical, and security sectors.

- Integrated Team: Hardware and software specialists working seamlessly together.

- Lifecycle Management: Proactive component tracking and risk management.

- Flexible Support: Augment your in-house team or deliver a complete turnkey solution, as needed.

Time to Migrate from PLC to Custom PCB?

or your PLC costs are starting to hurt your bottom line, now is the time to explore your options.

ByteSnap can help you assess the business case, map out a risk-managed transition, and deliver a robust, futureproof solution.

Schedule a call with our expert engineering consultants to get started.

Moving from PLC to Custom PCB: Frequently Asked Questions

How do I know if my volume justifies a custom PCB?

If you’re producing more than 100–1,000 units/year, or PLC costs are a significant part of your BOM, it’s time to run the numbers.

ByteSnap can help with a detailed cost-benefit analysis.

What’s the typical lead time for a custom PCB project?

Expect 6-12 months from initial specification to production-ready prototypes, depending on complexity.

Will I lose flexibility compared to a PLC?

No. A bespoke PCB is tailored to your needs, so you only pay for-and maintain-the features you actually use. Updates and new features can be managed through firmware and hardware revisions. Consider factoring in extra time for complex hardware designs depending on your requirements.

What about compliance and certification?

ByteSnap designs with industry standards in mind-including, CE, UL, ATEX, and more. We manage the certification process as part of our service.

How do you ensure reliability and long-term support?

We build in rigorous testing, robust design practices, and proactive component lifecycle management. ByteSnap also offers long-term support and can develop end-of-line test equipment for your production line.

Is a bespoke PCB suitable for low-volume products?

For very low volumes (under 100 units/year), a PLC is usually more cost-effective.

But if you have special requirements or expect volumes to grow, let’s talk-there may be a business case for a custom solution.

Founded in 2008, ByteSnap Design is an award-winning embedded systems design consultancy, offering a comprehensive range of services across the electronic product development lifecycle.

A highly skilled team of over 40 hardware and software engineers, our expertise spans several sectors, including IoT, automotive, industrial, medical, and consumer electronics.

The engineering consultants on the ByteSnap Editorial Team share their knowledge and practical tips to help you streamline your product development and accelerate designs to market successfully.

With their deep technical expertise and practical experience, they aim to provide valuable insights and actionable tips to guide you through the complex world of electronic product design and development, to help you bring innovative, reliable, and secure electronic products to market quickly and cost-effectively.