TL; DR - Your top ATEX requirements 2026 trends queries answered

1: What is ATEX certification and why does it matter for 2026?

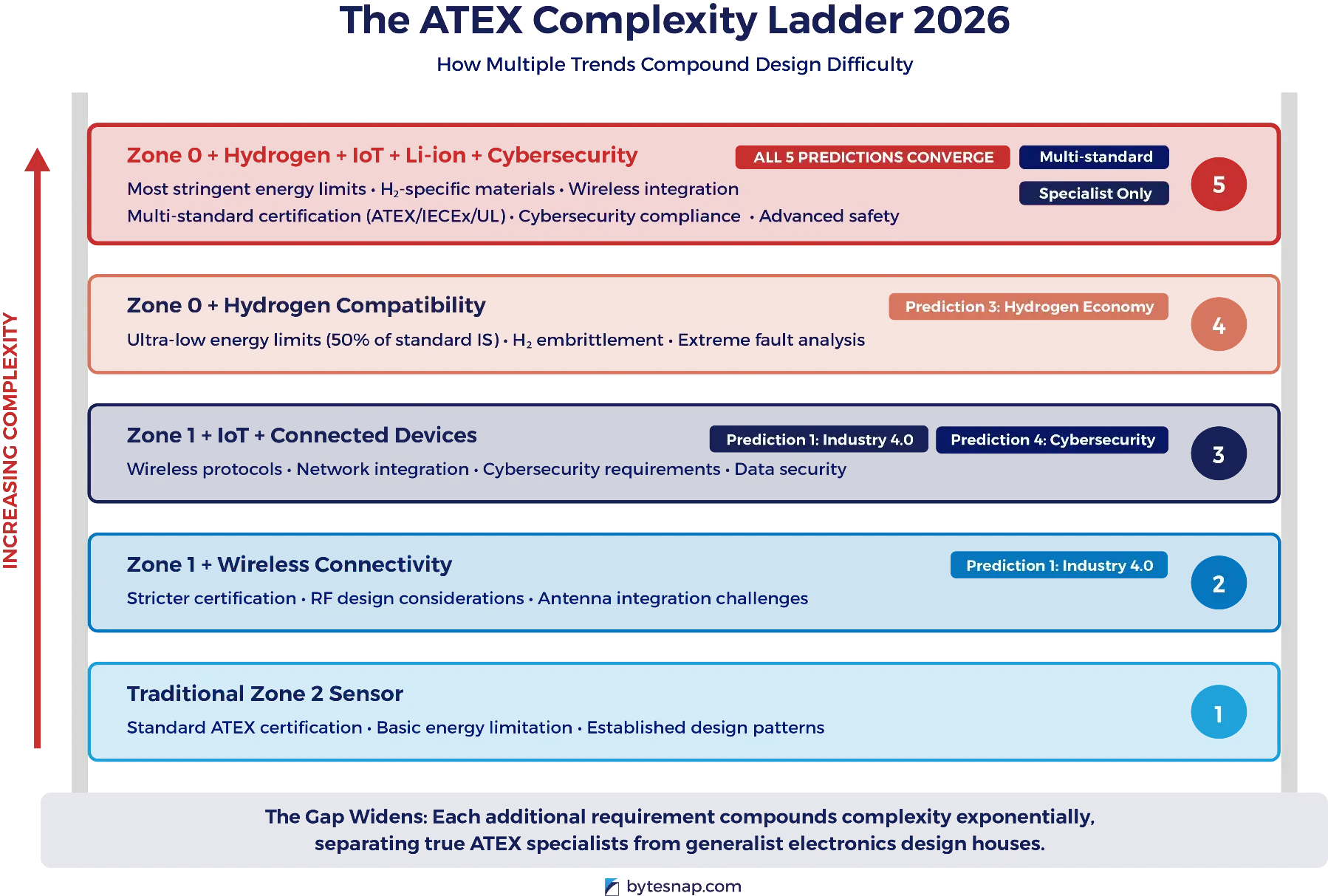

ATEX certification ensures that equipment used in potentially explosive atmospheres meets stringent EU safety standards. In 2026, ATEX compliance becomes more complex due to converging requirements: Industry 4.0 integration demands wireless connectivity and IoT capabilities, the hydrogen economy requires ultra-low energy designs for Zone 0 applications, cybersecurity frameworks like the EU Cyber Resilience Act add new compliance layers, and multi-region certification strategies (ATEX/IECEx/UL) are becoming the default approach for global manufacturers.

2: How is the hydrogen economy changing ATEX design requirements?

Hydrogen presents uniquely challenging conditions for ATEX designers. With ignition energy 16 times lower than methane (0.017 mJ vs 0.28 mJ) and a flammability range of 4-75% compared to methane's 5-15%, hydrogen applications demand even more conservative energy limitation designs than traditional hydrocarbon environments. The rapid buildout of green hydrogen infrastructure worldwide creates significant demand for intrinsically safe sensors, monitoring systems, and control equipment specifically engineered for hydrogen's extreme properties, including embrittlement effects and molecular ingress challenges.

3: Why must ATEX devices now meet cybersecurity requirements?

As intrinsically safe tablets, IoT sensors, and connected devices bring Industry 4.0 capabilities into hazardous areas, cybersecurity and intrinsic safety must be integrated from the earliest design stages. Whilst the ATEX Directive (2014/34/EU) focuses on explosion safety, manufacturers placing connected ATEX/IECEx devices on the EU market must now demonstrate secure-by-design practices due to new regulations such as the EU Cyber Resilience Act (CRA) and evolving standards under the Radio Equipment Directive. This creates a growing need for dual compliance: explosion safety (ATEX/IECEx) and product cybersecurity (CRA/IEC 62443/RED).4: What's driving the $12.2 billion ATEX equipment market in 2026?

Several factors: increased oil and gas operations, expansion of petrochemical and water treatment facilities, and emerging green hydrogen production plants in developing economies. The intrinsically safe equipment market is forecast to exceed $5.5 billion by 2030, with 7.45% CAGR driven by IoT-based monitoring, 5G connectivity, and edge computing. Around 200 workplace incidents related to explosive atmospheres occur annually in Europe, highlighting the importance of effective ATEX solutions and creating pressure for faster certification timescales whilst meeting stringent multi-standard requirements.

Table of Contents

ATEX requirements are changing faster than many realise.

As one of the development team for an award-winning ATEX Zone 0 sensor, WAND RDC, I’ve experienced firsthand how ATEX challenges separate specialists from generalists in the embedded systems space.

The trends I’ve listed here are borne of active projects, conversations with notified bodies, and the technical realities currently shaping our design decisions.

If you’re responsible for ATEX-certified equipment development, 2026 will demand more from your engineering teams than any previous year.

1. Industry 4.0 Integration Accelerates Digital Transformation in Hazardous Environments

The intrinsically safe equipment market is forecast to reach over $5.5 billion by 2030. That’s growth of CAGR of 7.45% driven by IoT-based monitoring, 5G connectivity, edge computing and other Industry 4.0 technologies.

There’s a shift amongst manufacturers away from only using traditional fixed, wired SCADA systems with centralised terminals.

In addition, they’re deploying intrinsically safe tablets and wearables for real-time data capture, predictive maintenance, and remote collaboration in hazardous locations.

Certified industrial Ethernet switches, remote I/O modules, and intrinsically safe wireless networks now enable secure data collection from hazardous zones for real-time monitoring.

During 2026, I anticipate further widespread deployment of ATEX certified IoT hubs, wireless sensors, and AI-enabled edge devices that transform hazardous environment operations whilst maintaining strict safety compliance.

Impact on Design:

Electronics designers should expect to integrate advanced wireless connectivity (5G, Wi-Fi 6), edge computing processors, and multiple sensor interfaces whilst maintaining intrinsic safety certification.

This may well increase design complexity significantly and need a deeper understanding of both digital communications protocols and energy limitation principles.

2. $12.2 Billion Market by 2026: What's Fuelling ATEX Equipment Demand

The intrinsically safe equipment market is forecast to reach over $5.5 billion by 2030, according to industry analysts.

That’s growth of CAGR of 7.45% driven by IoT-based monitoring, 5G connectivity, edge computing and other Industry 4.0 technologies.

There’s a shift amongst manufacturers away from only using traditional fixed, wired SCADA systems with centralised terminals.

In addition, they’re deploying intrinsically safe tablets and wearables for real-time data capture, predictive maintenance, and remote collaboration in hazardous locations.

Certified industrial Ethernet switches, remote I/O modules, and intrinsically safe wireless networks now enable secure data collection from hazardous zones for real-time monitoring.

During 2026, I anticipate further widespread deployment of ATEX certified IoT hubs, wireless sensors, and AI-enabled edge devices that transform hazardous environment operations whilst maintaining strict safety compliance.

Impact on Design:

Manufacturers will come under pressure to reduce certification timescales and costs whilst meeting stringent requirements across several global standards (ATEX, IECEx, UL). In turn, this will require more sophisticated pre-compliance testing and design validation processes.

Aftermarket services including inspection, recertification, and modernisation already represent around 25% of market revenues, creating opportunities for design houses that can support product lifecycle management.

3. Green Hydrogen Economy Creates New ATEX Design Challenges and Opportunities

The development of green hydrogen plants is creating significant demand for materials and components needed to construct electrolyser stacks, with the hydrogen economy becoming a major infrastructure focus for 2026 and beyond.

Hydrogen production, storage, and distribution facilities represent extremely hazardous environments with typically ATEX Zone 0 and Zone 1 areas.

Hydrogen has exceptionally low ignition energy (0.017 mJ compared to methane’s 0.28 mJ) and wide flammability range (4-75% in air versus methane’s 5-15%).

Over the next 12 months, the rapid buildout of hydrogen infrastructure worldwide, driven by net-zero targets and energy transition policies, will generate greater demand for intrinsically safe sensors, monitoring systems, leak detection equipment, and control systems designed specifically for hydrogen applications.

Impact on Design:

Electronics engineers will need specialised expertise in hydrogen-specific hazards, which require even more conservative energy limitation designs than traditional hydrocarbon applications.

Other key factors include understanding hydrogen embrittlement effects on enclosure materials, and consideration of extremely small molecule size for ingress protection.

I’d say this represents one of the most technically demanding frontiers in ATEX design.

4. Cybersecurity Is Rapidly Becoming a Core Requirement for Connected ATEX/IECEx Devices

As intrinsically safe tablets and connected IoT devices continue to bring Industry 4.0 capabilities into brownfield hazardous-area installations, designers must now integrate cybersecurity and intrinsic safety from the earliest stages of product development.

The accelerating deployment of 5G, private industrial networks, and IIoT infrastructure through 2024–25 has enabled real-time data transfer from wearables and mobile devices even in remote offshore environments.

However, this same connectivity significantly expands potential attack surfaces.

While the ATEX Directive (2014/34/EU) itself still focuses on explosion safety, manufacturers placing connected ATEX/IECEx devices on the EU market will increasingly need to demonstrate secure-by-design practices due to new cybersecurity regulations such as the EU Cyber Resilience Act (CRA) and evolving harmonised standards under the Radio Equipment Directive.

As these regulations come into force, notified bodies and assessors are expected to place greater scrutiny on cybersecurity evidence during conformity assessment, especially for network-connected IS equipment.

The practical impact is a growing need for dual compliance: explosion safety (ATEX/IECEx) and product cybersecurity (CRA/IEC 62443/RED).

Impact on Design:

Hardware and embedded engineers will need combined expertise in functional safety and cybersecurity frameworks such as IEC/ISA 62443 and CRA requirements.

Designs will increasingly require secure boot, signed and authenticated firmware, encrypted communications, and secure OTA update mechanisms, all implemented without violating intrinsic-safety energy limits or introducing uncertified components.

This convergence means connected ATEX/IECEx products can no longer be designed in isolation. They require multidisciplinary engineering teams, integrated development lifecycles, and certification strategies that treat safety and cybersecurity as co-dependent rather than separate considerations.

5. Multi-Region Certification Is Becoming the Default Approach for Hazardous-Area Equipment

Global manufacturers are increasingly moving toward multi-standard certification strategies as hazardous-area regulations evolve across different regions.

While enforcement and adoption vary by jurisdiction, periodic updates to the NEC (NFPA 70) and CEC, ongoing maintenance of ATEX standards in the EU, and continued international uptake of the IECEx scheme are collectively increasing pressure on operators to replace outdated equipment and ensure compliance with current norms.

Certification remains inherently fragmented, with separate pathways for IECEx, ATEX/CE marking, and North American approvals (UL/FM/CSA).

These parallel processes add development cost and extend lead-times, driving demand for equipment designed from the outset to meet multiple regional requirements.

At the same time, ongoing harmonisation efforts, including the alignment of IEC 60079 series standards within IECEx and the EU’s publication of harmonised standards to support ATEX, are gradually reducing unnecessary test duplication, even though full convergence is still an incremental process.

Against this backdrop, manufacturers aiming for global markets are finding it increasingly advantageous to pursue simultaneous certification across IECEx, ATEX, and North American schemes rather than sequential approvals.

This trend is reinforced by strong industrial growth in the Asia-Pacific region, where governments continue to refine safety frameworks and enforce stricter compliance, creating significant opportunities for companies offering internationally compatible designs.

Impact on Design:

Design teams will need to adopt a “design for global certification” mindset from the start of a project.

This includes understanding how protection concepts and hazardous-area classifications differ between zone-based (IECEx/ATEX) and division-based (NEC/CEC) systems, and planning architectures that can be certified across multiple jurisdictions with minimal redesign.

Engineering consultancies that offer integrated services, spanning:

- early-stage design review

- pre-compliance testing

- and coordination with multiple notified bodies and certification agencies

will provide a valuable competitive advantage as certification complexity remains one of the most significant barriers to market entry for ATEX/IECEx/IS equipment.

What This Means for Your Projects

These trends are set to reshape how we approach ATEX design in the months ahead.

From my perspective at the engineering coalface, the businesses that will thrive are those treating these changes as competitive differentiators, rather than compliance burdens.

The convergence of functional safety, cybersecurity, advanced battery technology, and global certification requirements creates barriers to entry that specialist design houses are uniquely positioned to navigate.

At ByteSnap Design, we’re already integrating these considerations into every ATEX project from day one, because retrofitting compliance simply doesn’t work in intrinsically safe systems.

Whether you’re developing your first Zone 0 device or modernising a legacy product line, the main question isn’t if these trends will affect you, but how quickly you’ll adapt your design approach to stay ahead of them.

Ready to discuss expert ATEX design engineering support? Let's talk

Further reading

- Intrinsically Safe Equipment Market Analysis – Mordor Intelligence

- Hazardous Area Equipment Market Growth Report

- ATEX Electrical Safety Barrier Market Forecast 2033

- ATEX Certification for the European Union – UL Solutions

- Understanding ATEX and IECEx for Hazardous Areas

- Geographic Acceptance of Explosion Proof Certification

- IoT Platform for Hazardous Locations – Aegex Technologies

- Intrinsically Safe Tablets for Critical Industry 4.0

- 2025 Trends in Intrinsically Safe Wearable Technology

- Explosion-proof Lithium Battery Certifications Explained

- ATEX Battery Design – Ex Dynamics

- 2025-2026 Regulatory Changes for Lithium-Ion Batteries

- HSE Statistics – Work-Related Fatal Injuries 2024/25

- Key Health and Safety Statistics for 2025 – HSE Network

- Materials for Green Hydrogen Production 2026-2036 – IDTechEx

- Hydrogen Storage Technology and Challenges Review

Dunstan is a chartered electronics engineer who has been providing embedded systems design, production and consultancy to businesses around the world for over 30 years.

Dunstan graduated from Cambridge University with a degree in electronics engineering in 1992. After working in the industry for several years, he co-founded multi-award-winning electronics engineering consultancy ByteSnap Design in 2008. He then went on to launch international EV charging design consultancy Versinetic during the 2020 global lockdown.

An experienced conference speaker domestically and internationally, Dunstan covers several areas of electronics product development, including IoT, integrated software design and complex project management.

In his spare time, Dunstan enjoys hiking and astronomy.